연속 가동조건의 효율적인 펌프 (Efficient pumps for continuous use)

본문

연속 가동조건의 효율적인 펌프

높은 유량에서의 효율성 그리고 높은 에너지 효율성의 펌프 동작실현, 극저온(액화가스)에서부터 매우 높은 온도까지의 다양한 온도범위의 유체 대응

Efficient pumps for continuous use

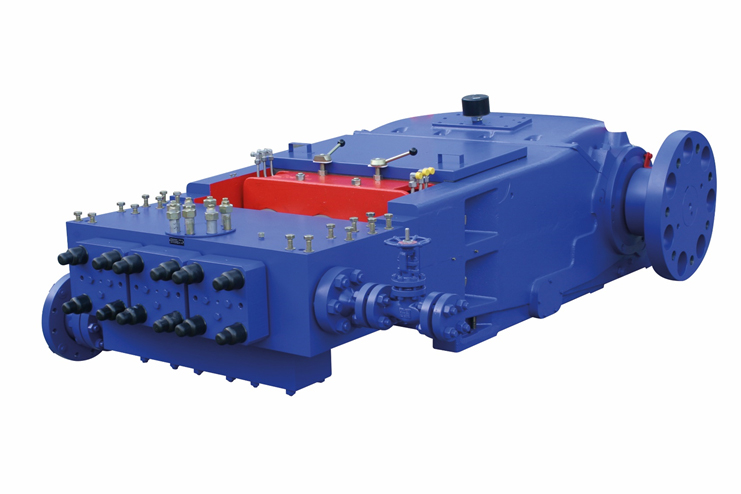

Pumping aggressive or other high-volume and high-pressure problem fluids is the specialty of URACA plunger pumps.

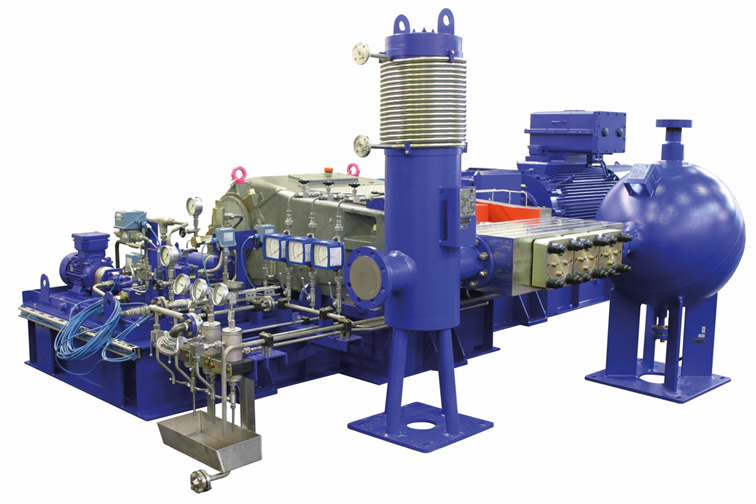

High-pressure plunger pumps of the large pump series from URACA are designed and built for the most diverse applications in terms of performance and pumped medium, whereby the machines are usually operated in continuous operation. The maximum drive power is 2600 kW. The flow rates can be up to 11,000 l / min, the operating pressure can reach 3,000 bar and more. Suction and pressure side dampers enable pulsation-poor and thus safe operation of the entire system. The particular advantage here is the high volumetric efficiency and the associated energy-efficient operation of the pumps.

The pumping of neutral and aggressive, thin and viscous as well as abrasive media is no problem for URACA pumps, whereby the temperature ranges can vary from extremely cold (liquefied gases) to very high temperatures.

For example, URACA pumps are used in refineries, spray-feeding, detergent production or fertilizer production, as well as in the processing of residual oils or coal liquefaction.

The high-pressure plunger pumps from Bad Urach can also be found in rolling mills for descaling, bearing lubrication or when driving large hydraulic forging and extrusion presses. An essential role also plays the promotion of the most diverse liquefied gases under high pressure. Examples of this are liquid ammonia or liquid CO2, as used in high-pressure extraction. From the large number of other fields of application, only the uses in connection with oil and natural gas exploration are mentioned here, be it as a pressure test pump for pipelines or as a pump-in pump for salt water, methanol or other media.

The use of plunger pumps is always associated with pulsations for physical reasons - regardless of the pump make. According to the requirements of the respective system, these pulsations must often be reduced. Especially for installation in pressure pipes, URACA provides pulsation dampeners according to the reflection principle - so-called resonators. These dampers have no internal parts and thus work completely maintenance-free - a cost advantage that must not be overlooked.

URACA has extensive know-how in the design, construction and construction of resonators. The choice of material is made according to the requirements of the respective pumped medium.